Precyzyjna spawarka punktowa DC: wydajne, dokładne i przyjazne dla środowiska rozwiązanie spawalnicze

2025-01-06 14:18Precision DC spot welder has become an ideal choice for modern precision welding with its excellent performance and environmental advantages.

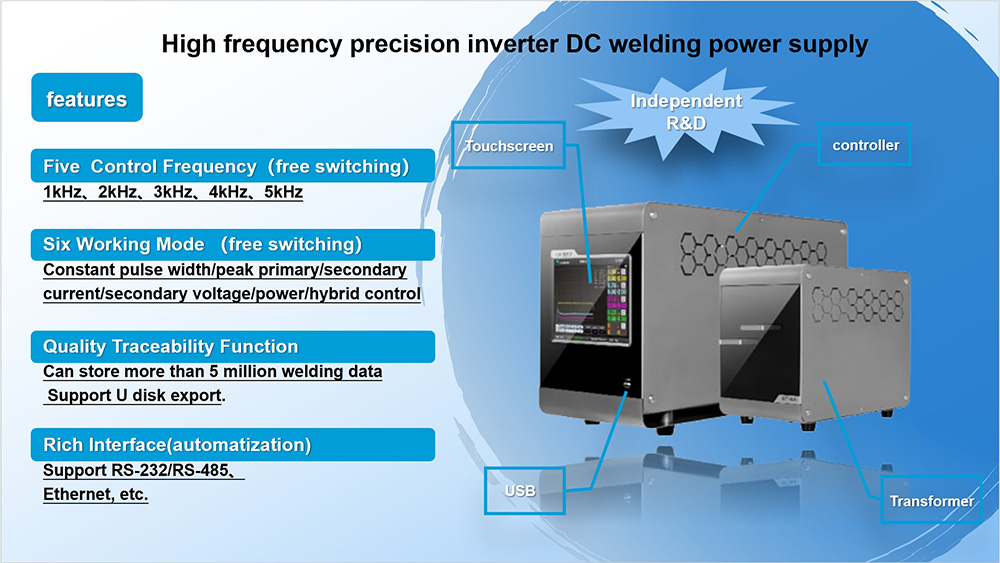

Precision DC spot welding machine has good welding effect, and the time adjustment resolution of precision spot welding machine is more accurate and the control accuracy is high. The response speed of feedback control of precision spot welding machine with high service quality is significantly faster, and the output stability is good. The output current of precision spot welding machine is pulsating DC, and spot welding machine is continuous DC output under the action of loop inductance, with high thermal efficiency and stable welding heat input. High-quality precision spot welding machine can quickly realize welding operation and ensure more excellent welding. The operation of completing welding in an instant can also ensure that the welding point is more stable. Modern precision spot welding machine improves the system and integrates the needs of environmental protection use, so that there will be no smoke, noise and pollutants in the welding process, thereby maximizing the environmental requirements. Hand spot welder is one of the important manifestations of modern environmental protection production and one of the important means to reduce pollution.

Core advantages:

Excellent welding effect: DC output, concentrated heating, short welding time, good forming, first-class traceless effect, suitable for high-end welding such as computer cases.

Precise and efficient control: High time adjustment resolution, high control accuracy, fast response speed, stable output, high thermal efficiency, stable welding heat input, instant welding, stable and reliable welding points.

Environmental protection and energy saving: System improvement, no smoke, noise and pollutants, in line with environmental protection production requirements. The transformer works at high frequency, with low loss, DC output improves power factor, and has significant energy saving effect.

Easy and flexible operation: The equipment has a reasonable structure, easy installation, compact transformer, good portability, and can be applied in different environments. Programmable control supports a variety of welding modes and parameter settings to meet diverse needs.

Application fields:

Precision DC spot welders are widely used in welding materials such as tungsten, molybdenum, nickel, iron, copper, aluminum, silver, stainless steel, etc., especially for precision welding in precision instruments, electronic components, medical devices and other fields.

Choose precision DC spot welders, you will get:

More efficient welding experience

More accurate welding control

More environmentally friendly production methods

Wider application scenarios

Precision DC spot welders help you easily achieve high-quality welding!